Ford Rouge Complex things to do, attractions, restaurants, events info and trip planning

Basic Info

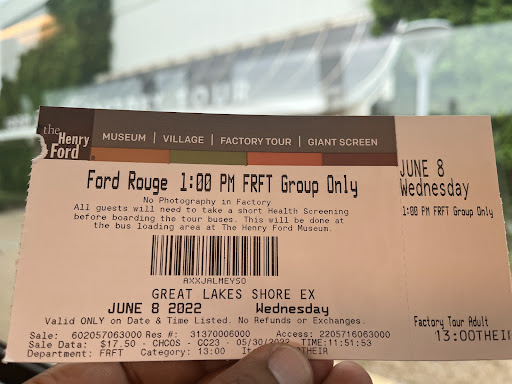

Ford Rouge Complex

Dearborn, MI 48120

4.8(501)

Open 24 hours

Save

spot

spot

Ratings & Description

Info

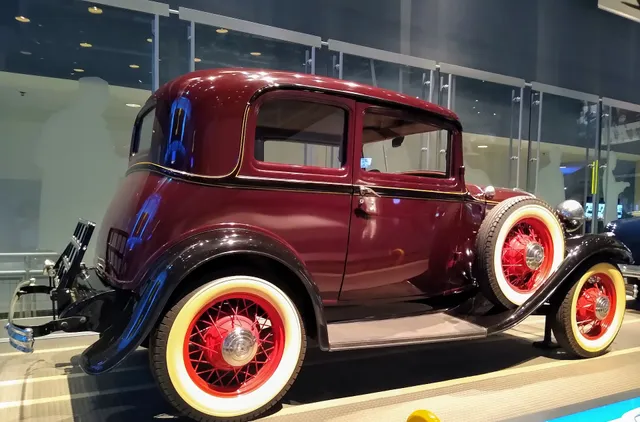

The Ford River Rouge complex is a Ford Motor Company automobile factory complex located in Dearborn, Michigan, along the River Rouge, upstream from its confluence with the Detroit River at Zug Island.

Cultural

Family friendly

Accessibility

attractions: , restaurants: Bisher Market, Grub Inn Pizza & Grill, Yemen Kitchen (MAZA), local businesses: DTP Final Assembly, Gate 6 Ford Rouge Complex, Ford Dearborn, Wolverine Ford Trk Sls In, Dearborn Produce Wholesale LLC, Mazafoods, Dearborn Stamping Plant LCL Docks

Learn more insights from Wanderboat AI.

Learn more insights from Wanderboat AI.Plan your stay

Pet-friendly Hotels in Dearborn

Find a cozy hotel nearby and make it a full experience.

Affordable Hotels in Dearborn

Find a cozy hotel nearby and make it a full experience.

The Coolest Hotels You Haven't Heard Of (Yet)

Find a cozy hotel nearby and make it a full experience.

Trending Stays Worth the Hype in Dearborn

Find a cozy hotel nearby and make it a full experience.

Reviews

Live events

Foreplay Fridays At Hideaway In Southfield

Fri, Feb 6 • 9:00 PM

29267 Southfield Road, Southfield, MI 48076

View details

O Horrors! Its Murder! A Murder Mystery

Sat, Feb 7 • 7:00 PM

41415 West 9 Mile Road Novi, MI 48375

View details

Karaoke @ Taylor AC Lounge - Taylor, MI

Mon, Feb 9 • 7:00 PM

25955 Ecorse Road Taylor, MI 48180

View details

Nearby restaurants of Ford Rouge Complex

Bisher Market

Grub Inn Pizza & Grill

Yemen Kitchen (MAZA)

Bisher Market

4.5

(466)

$

Open until 8:00 PM

Click for details

Grub Inn Pizza & Grill

4.2

(98)

$

Open until 11:00 PM

Click for details

Yemen Kitchen (MAZA)

4.0

(48)

$

Open until 10:00 PM

Click for details

Nearby local services of Ford Rouge Complex

DTP Final Assembly

Gate 6 Ford Rouge Complex

Ford Dearborn

Wolverine Ford Trk Sls In

Dearborn Produce Wholesale LLC

Mazafoods

Dearborn Stamping Plant LCL Docks

DTP Final Assembly

4.4

(135)

Click for details

Gate 6 Ford Rouge Complex

4.1

(16)

Click for details

Ford Dearborn

4.4

(560)

Click for details

Wolverine Ford Trk Sls In

4.3

(56)

Click for details