Jeep slop shop things to do, attractions, restaurants, events info and trip planning

Basic Info

Jeep slop shop

2031 Anders Ln, Kemah, TX 77565

4.9(125)

Open until 12:00 AM

Save

spot

spot

Ratings & Description

Info

Adventure

Outdoor

attractions: Kemah Gardens, Butler Longhorn Museum, Fellowship Community Church, 57-Acre Park, restaurants: , local businesses: Redline Print, Triple T Holsters, LLC, Taylored Vinyl, LLC, Camp Bow Wow Kemah, Discount Depot, Samano's Hobbies, Kemah Furniture Outlet, Stix n' Rig'n Inc., Ultimate Innovations, Kemah Plaza

Learn more insights from Wanderboat AI.

Learn more insights from Wanderboat AI.Phone

(281) 549-7609

Website

jeepslopshop.com

Open hoursSee all hours

SunClosedOpen

Plan your stay

Pet-friendly Hotels in Kemah

Find a cozy hotel nearby and make it a full experience.

Affordable Hotels in Kemah

Find a cozy hotel nearby and make it a full experience.

The Coolest Hotels You Haven't Heard Of (Yet)

Find a cozy hotel nearby and make it a full experience.

Trending Stays Worth the Hype in Kemah

Find a cozy hotel nearby and make it a full experience.

Reviews

Live events

Business Analyst (CBAP) Classroom Training in New Baytown, TX

Tue, Jan 27 • 9:00 AM

1300 Rollingbrook Drive, Baytown, TX 77521

View details

Guitar Lessons in Baytown

Wed, Jan 28 • 7:00 PM

802 Mabry Street Baytown, TX 77520

View details

Valentines Hearts Paint & Sip

Fri, Jan 30 • 10:30 AM

2805 East League City Parkway League City, TX 77573

View details

Nearby attractions of Jeep slop shop

Kemah Gardens

Butler Longhorn Museum

Fellowship Community Church

57-Acre Park

Kemah Gardens

4.7

(65)

Closed

Click for details

Butler Longhorn Museum

4.5

(59)

Open until 12:00 AM

Click for details

Fellowship Community Church

4.8

(17)

Open until 12:00 AM

Click for details

57-Acre Park

4.9

(9)

Open 24 hours

Click for details

Nearby local services of Jeep slop shop

Redline Print

Triple T Holsters, LLC

Taylored Vinyl, LLC

Camp Bow Wow Kemah

Discount Depot

Samano's Hobbies

Kemah Furniture Outlet

Stix n' Rig'n Inc.

Ultimate Innovations

Kemah Plaza

Redline Print

4.8

(30)

Click for details

Triple T Holsters, LLC

4.9

(141)

Click for details

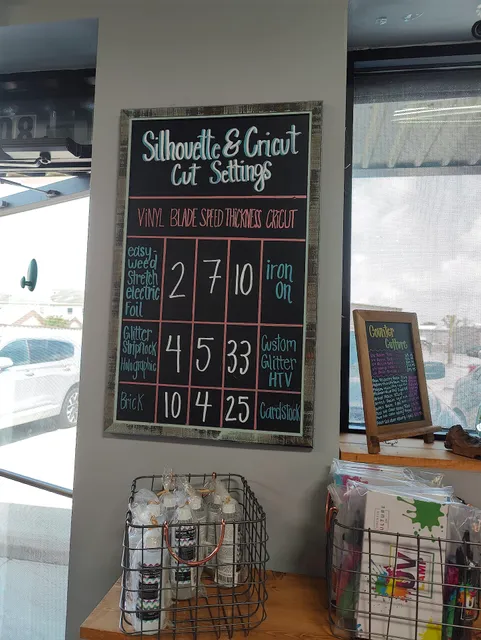

Taylored Vinyl, LLC

4.9

(142)

Click for details

Camp Bow Wow Kemah

4.8

(195)

Click for details