Knight Foundry things to do, attractions, restaurants, events info and trip planning

Basic Info

Knight Foundry

81 Eureka St, Sutter Creek, CA 95685

4.7(93)

Open 24 hours

tickets

Save

spot

spot

Ratings & Description

Info

Knight Foundry, also known as Knight's Foundry and Shops, is a cast iron foundry and machine shop in Sutter Creek, California. It was established in 1873 to supply heavy equipment and repair facilities to the gold mines and timber industry of the Mother Lode.

Cultural

Family friendly

Accessibility

attractions: Sutter Creek Theatre, La Mesa Sutter Creek, Scott Harvey Wines Tasting Room, Raven's Reach Winery, Sutter Creek Visitor Center, Miners' Bend Park, restaurants: Gold Dust Pizza Sutter Creek, Cavana's Pub and Grub, Rosa's Cocina, Choc-O-Latte, Elvis' Rhythm and Brews Sutter Creek, Sina's Backroads Café, Simply Bubbles, Baiocchi Wines Tasting Room, local businesses: The Clothes Mine, Jumping Frog Games, On Purpose, The Music Box Company, Antique Gardener, Tigby Hill Vintage, Water Street Antiques & Interiors, Blondie's Boutique Classy Consignments, Old Hotel Antiques, Coming Attractions

Learn more insights from Wanderboat AI.

Learn more insights from Wanderboat AI.Phone

(209) 560-6160

Website

knightfoundry.com

Plan your stay

Pet-friendly Hotels in Sutter Creek

Find a cozy hotel nearby and make it a full experience.

Affordable Hotels in Sutter Creek

Find a cozy hotel nearby and make it a full experience.

The Coolest Hotels You Haven't Heard Of (Yet)

Find a cozy hotel nearby and make it a full experience.

Trending Stays Worth the Hype in Sutter Creek

Find a cozy hotel nearby and make it a full experience.

Reviews

Live events

A Highway 49 Drive: A Self-Guided Audio Tour from Jackson to Angels Camp

Fri, Feb 20 • 12:00 AM

Jackson

View details

Barrel Room Wine Tasting with the Winemaker

Fri, Feb 20 • 3:00 PM

Sutter Creek, California, 95685

View details

Incident Safety Awareness for the Hired Vendor Ione

Sat, Feb 21 • 8:00 AM

Jackson Valley Fire Protection District, 2701 Quiver Drive, Ione, United States

View details

Nearby attractions of Knight Foundry

Sutter Creek Theatre

La Mesa Sutter Creek

Scott Harvey Wines Tasting Room

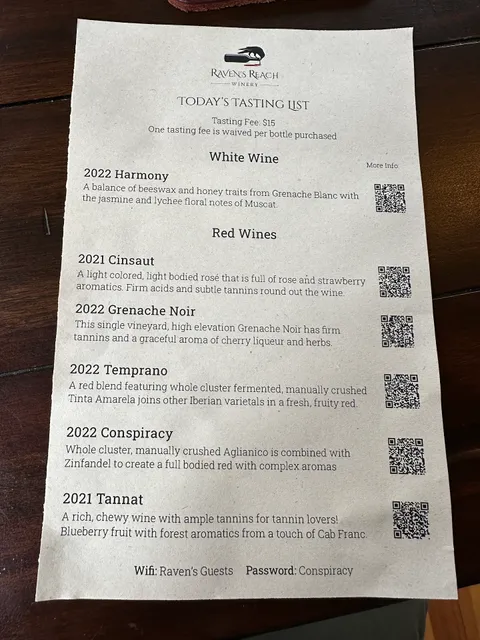

Raven's Reach Winery

Sutter Creek Visitor Center

Miners' Bend Park

Sutter Creek Theatre

4.7

(69)

Open until 12:00 AM

Click for details

La Mesa Sutter Creek

4.9

(93)

Closed

Click for details

Scott Harvey Wines Tasting Room

4.9

(40)

Closed

Click for details

Raven's Reach Winery

4.9

(23)

Closed

Click for details

Nearby restaurants of Knight Foundry

Gold Dust Pizza Sutter Creek

Cavana's Pub and Grub

Rosa's Cocina

Choc-O-Latte

Elvis' Rhythm and Brews Sutter Creek

Sina's Backroads Café

Simply Bubbles

Baiocchi Wines Tasting Room

Gold Dust Pizza Sutter Creek

4.7

(824)

$

Closed

Click for details

Cavana's Pub and Grub

4.5

(493)

$

Closed

Click for details

Rosa's Cocina

4.3

(63)

$$

Closed

Click for details

Choc-O-Latte

4.7

(143)

$

Open until 5:00 PM

Click for details

Nearby local services of Knight Foundry

The Clothes Mine

Jumping Frog Games

On Purpose

The Music Box Company

Antique Gardener

Tigby Hill Vintage

Water Street Antiques & Interiors

Blondie's Boutique Classy Consignments

Old Hotel Antiques

Coming Attractions

The Clothes Mine

4.7

(23)

Click for details

Jumping Frog Games

4.4

(19)

Click for details

On Purpose

4.9

(18)

Click for details

The Music Box Company

4.8

(19)

Click for details